Exploring Powder Coating for Composites

Advancements in powder coating technology make it a viable surface finish for a growing number of composite applications.

Composites World September 2024 Vol 10 No 9

Author: Scott Francis, Editor-in-Chief

From aerospace and automotive to sporting goods and beyond, composite materials are finding their way into a rapidly growing number of applications. However, achieving the perfect finish for composites can be a challenge. Enter powder coating — a finishing process traditionally used for metals, now gaining traction for nonmetallic substrates.

Powder coating involves applying a dry powder to a substrate through an electrostatic application process. The coated part is then cured under heat to form a durable, protective and aesthetically pleasing finish. The process offers numerous advantages, including a uniform finish, improved resistance to chipping and scratching, and environmental benefits due to the absence of hazardous air pollutants (HAPs) and volatile organic compounds (VOCs).

Despite its advantages, there are several important considerations for using powder coating as a finish for composites. One of the primary considerations is the thermal sensitivity of the substrates. Traditional powder coating processes require curing at high temperatures, typically 150-200°C. Many composites, however, may not withstand these temperatures without degrading or deforming. Low temperature powder coatings have been developed to address this issue. These coatings cure at significantly lower temperatures, around 120-150°C, making them suitable for temperature-sensitive substrates. Additional low- temperature solutions include powder coatings that use ultraviolet (UV) light for the cure process, offering the potential for even less heat exposure for heat-sensitive materials.

For parts with low temperature thresholds, such as composites, an ultraviolet (UV) curable powder coating can be an ideal solution.

One company at the forefront of these innovations is Keyland Polymer (Cleveland, Ohio, U.S.), known for its work in UV curable powder coating. Keyland’s story is intertwined with its sister company, DVUV (Cleveland), which reportedly introduced the first UV curable powder coat line in North America. Initially focused on powder coating medium-density fiberboard (MDF), DVUV quickly realized the potential for UV curable powder coatings beyond traditional substrates. This led to the formation of Keyland Polymer in 2006, with a mission to advance UV curable powder coating technology through continuous research and development (R&D).

Keyland’s primary product, UVMax®, has become synonymous with high-quality UV curable powder coatings. Over the years, the company has expanded its expertise to include coatings for metals, plastics and composites, including carbon fiber materials. This diversification has positioned Keyland as a leader in coating heat-sensitive and non-conductive substrates that traditional powder coatings struggle to handle.

“Powder coating provides a very decorative and functional coating in one coating layer, offering tremendous efficiencies

compared to other technologies,” says Andrew Walton, business development manager with Keyland Polymer. “A lot of the R&D work that we still continue to do is for those non-conductive heat-sensitive substrates that you couldn’t traditionally powder coat — parts that you would traditionally coat with wet paint. We’re really excited about coating these materials because we can provide the attributes of powder coating to substrates that you couldn’t traditionally do it with, providing high transfer efficiency [TE] and a very durable finish.”

TE refers to the percentage of a coating or paint that adheres to an intended surface compared to the amount of wasted material. Due to its application process using electrostatic spray guns to deposit charged material onto a substrate, powder coating is capable of delivering high TE.

Keyland Polymer’s UV powder coatings have been used in various industries, including sports and recreation equipment, aerospace and automotive. In the sports industry, for example, the coatings provide enhanced durability and performance for products like bicycles, tennis rackets and golf clubs. In aerospace and automotive sectors, the company is working on R&D projects to explore the use of its coatings for interior components, as well as functional coatings that offer specific performance characteristics.

Walton says that the company’s in-house resin manufacturing capabilities enable it to tailor the resin formulations to meet the unique needs of different applications. This flexibility has enabled Keyland to develop coatings with high chemical resistance, UV fade resistance and other specialized properties.

UV Cure Powder Coating

In addition to introducing the risk of deformation or degradation of composite or plastic parts, excessive heat during the cure process can affect the mechanical properties of composites, such as tensile strength and elasticity. UV cure powder coatings are particularly useful for coating such materials because they cure instantly when exposed to UV light energy, which helps mitigate the risk of altering the material’s properties. By using UV light to cure the coating, it is possible to achieve a durable, high-quality finish without damaging the substrate.

Keyland Polymer marketing manager Rebecca Lonczak explains: “Our standard UV formulation cures a lot lower than any

other low-temperature or traditional thermoset powder coating. For parts that have these lower temperature thresholds, UV cure powder coating is an ideal solution.”

Lonczak notes that the application equipment for UV powder coatings is similar to traditional powder coatings, but the key difference is the inclusion of a photoinitiator in the powder formulation and the need for UV light to complete the curing process.

Implementing UV powder coatings does require specific equipment and process considerations. “The powder and system go

hand in hand,” Walton says.

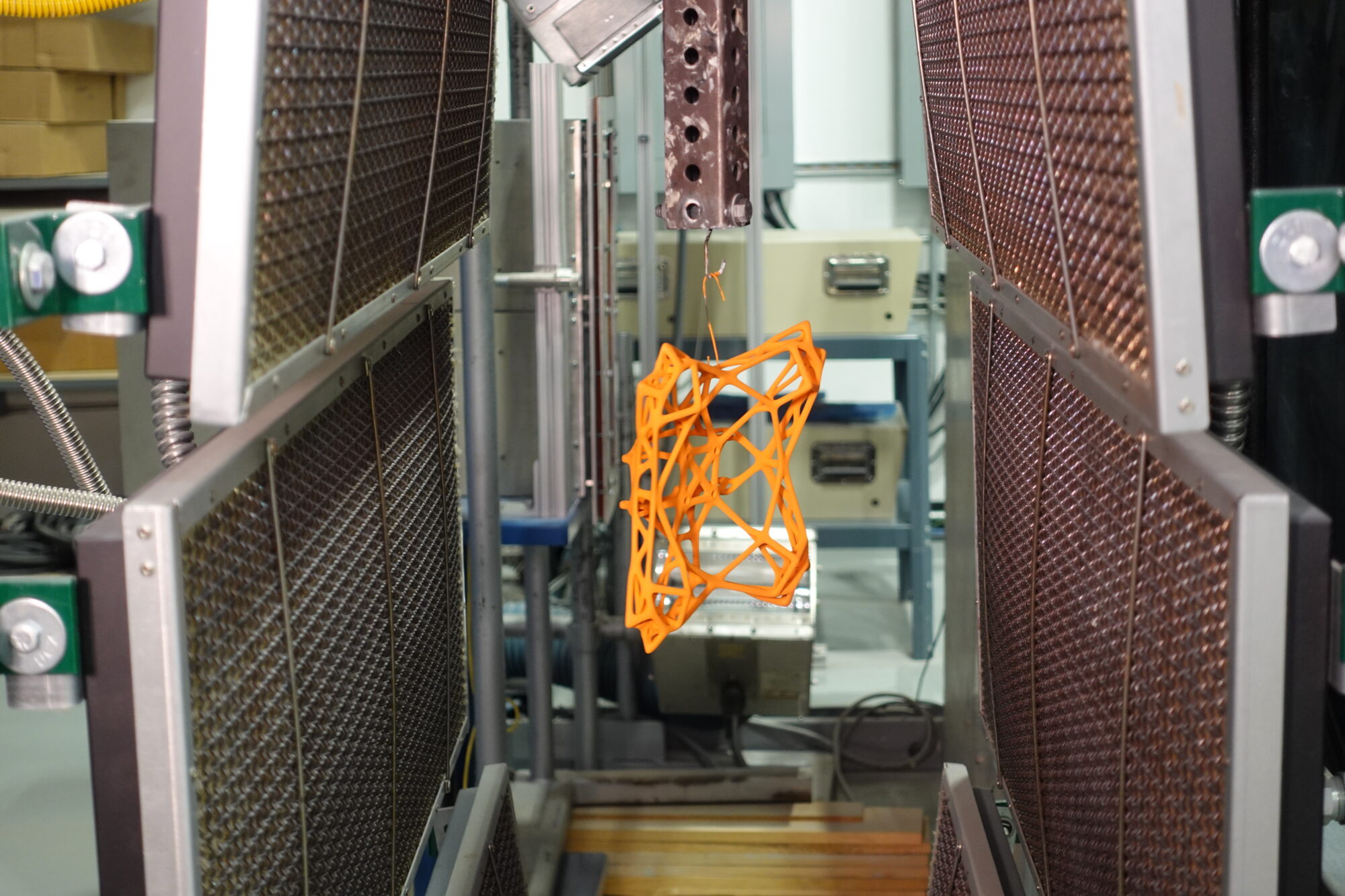

The process involves two distinct steps: melting and curing. The powder must be heated to flow out, which can be achieved using various heat sources, including convection and infrared (IR) heat. Once the powder has flowed out and is at an elevated temperature, it needs to be exposed to UV light for curing and crosslinking.

After a part is coated with UV cure powder, heat is applied using convection or infrared (IR) heat. Once the powder has melted it is then cured using UV light.

Additional Considerations

In addition to requiring a lower temperature cure, composite parts require some additional consideration prior to powder coating.

COMPLEX GEOMETRY: Carbon fiber parts often feature intricate shapes and contours, which can make uniform powder applications challenging. Advanced application techniques, such as electrostatic spray guns with adjustable nozzles, can help achieve even coverage. Rotating or tilting the part during application can also ensure that powder reaches all surfaces.

SURFACE PREPARATION: Prior to the coating process, proper surface preparation is crucial for ensuring adhesion and durability of the powder coating. Carbon fiber and composite parts often have smooth, non-porous surfaces that can be challenging for coatings to adhere to. Surface preparation techniques such as sandblasting, chemical etching or applying a primer can enhance adhesion. When dealing with composites, it is essential to select a method that does not damage the fibers or the resin matrix.

ELECTRIC CONDUCTIVITY: Regarding adhesion, the powder coating process relies on electrostatic attraction to hold the powder in place before curing. Carbon fiber is inherently conductive, which can aid in powder application. However, the conductivity can vary depending on the composite’s formulation and fiber orientation. Because ensuring a consistent and adequate electrostatic charge across the entire part is vital, techniques such as using a conductive primer or grounding the part can improve the application process.

Walton says that numerous conductive primers and adhesive promoters are available. In fact, Keyland has one such primer specifically designed for composite parts. Parts are sprayed or dipped prior to powder coating depending upon the part complexity and the process constraints of the system.

Looking Ahead

Keyland Polymer is continually pushing the boundaries of UV powder coating technology. The company is actively researching

ways to lower the curing temperatures even further, with some projects targeting temperatures as low as 100°C. Such advancements are opening up new possibilities for coating heat-sensitive substrates and helping to expand the range of applications for UV powder coatings.

As the demand for lightweight, high-performance materials continues to grow, the development and refinement of powder coating processes for composites may play a role in helping advance various applications. Walton says applications such as electric vehicles, energy storage and aerospace R&D, particularly in the realm of advanced air mobility (AAM), are driving interest in using powder coating in new ways. “We’re definitely seeing an increase in requests for functional coatings and not as much decorative.”

Powder coating has much to offer as a finishing option given its promise of combining durability, protection, aesthetics and environmental benefits. With technological advancements addressing concerns over the thermal sensitivity of substrates and other challenges of using the material, powder coating is poised to play a growing role in composite applications.