A Silver Lining

Asia Pacific Coatings Journal Vol 34 No2 May 2021

Author: Michael Knoblauch, President Keyland Polymer UV Powder, LLC

Michael Knoblauch, Keyland Polymer UV Powder, LLC, looks at how the addition of a silver ion antimicrobial additive into UV cured powder coatings offers added protection for surfaces.

What was – is no more. COVID-19 has changed everything from how we live, socialize, work, go to school, shop and entertain. We have become much more aware of the spaces and environments we pass through and the objects we encounter each day. We think twice before turning a doorknob, placing purchases on the checkout counter, or working at a desk, asking ourselves “is it safe?” or “will I get sick?” Proper cleaning and disinfection have never been more at the front of our minds. What we took for granted, we no longer do. Our expectation for safety and safe products has drastically increased.

This expectation is contributing to the increased use of antimicrobial additives in everyday products. Pre-COVID-19, antimicrobials were primarily used in healthcare materials and related products where there is a perceived risk of infection. Product manufacturers are now using these additives in paints and coatings, in articles of clothing, cleaning products and anywhere there is risk of the transmission of infection. The Grand View Research Report values the 2019 global antimicrobial coatings market at US $7.1 bn and predicts a compound annual growth rate (CAGR) of 12.8% from 2020 to 2027.

Antimicrobial additive materials carry an important caveat: they only inhibit the reproduction of potentially harmful bacteria and micro-organisms. They do not kill bacteria and micro-organisms and are not a replacement for regular cleaning and environmental hygiene. Antimicrobial coatings used along with standard and regular cleaning practices of a product or in an environment can help stop the growth and spread of these harmful micro-organisms on surfaces. This article will discuss the addition of a silver ion antimicrobial additive into the formulation of UV cured powder coatings and the product applications and benefits.

Powder coating began in the late 1960s and is an economical and environmentally friendly finishing solution. When first introduced, powder coatings were electrostatically applied as a dry powder and then melted and cured with heat. Powder coating is most widely known for its use on metal substrates, however advancements in cure technology have enabled the use of powder coating on heat sensitive substrates, such as wood, plastics, composites and more. There are two main types of powder coatings, thermally cured and UV cured. Thermally cured coatings use only heat energy to cure the coating. UV cured powder coatings use ultraviolet light energy to cure. UV cured powder coating can be used on a variety of products including worksurfaces, doors, retail store fixtures and other ‘high touch’ products.

Using Silver For Added Protection

The silver ion in the antimicrobial coating attaches to the cell walls of a microbe, interrupting enzyme production and DNA replication. Silver is widely used as an antimicrobial agent and was even used by the oldest civilizations (Romans, Greeks and Egyptians) for centuries, achieving a reduction of micro-organisms, preventing infections or preserving water and food. Over the years, technology has evolved but the antimicrobial properties of silver have remained. Formulators add the antimicrobial additive during the powder manufacturing process, completely dispersing it in the coating. The antimicrobial agent persists for the entire lifetime of the coating. This gives the finished surface 24/7 antimicrobial protection and repeated cleanings do not diminish or degrade the efficacy of the coating.

Independent third-party testing using ISO 22196 standards was performed on surfaces coated with a UV cured powder coating containing a silver ion antimicrobial additive. After 24hr, the test confirmed E coli and Staphylococcus bacterial reproduction was reduced by more than 99.99%. It is important to restate that antimicrobial powder coatings do not eliminate the potential of harmful microbes nor do they replace normal cleaning practices. However, when used with standard cleaning practices antimicrobial coatings help prevent the growth and the buildup of microbes that can cause staining, odors and illness.

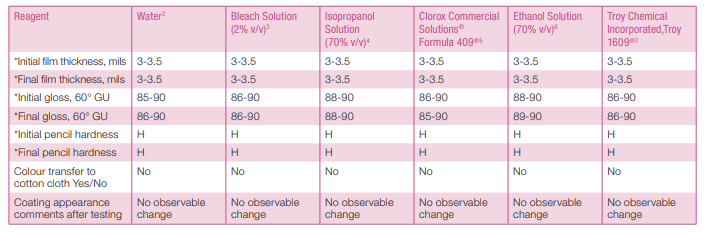

With an increased use in cleaning products and frequency of cleanings, it is important to evaluate the performance and durability of these surface coatings in their perspective environments. UV cured powder coatings on MDF were tested to determine the robustness of the surface when regularly cleaned using common household or commercial liquid cleaning products. This test is a modification of the NEMA LD 3-2000 method 3.4 Cleanability/ Stain Resistance, 3.4.5 and 25 cycles are considered one cleaning for the purpose of this test procedure (Table 1).

The test results confirmed that the use of the cited cleaning products causes no observable or measurable change in surface properties, color fastness, pencil hardness, film build, or gloss loss for the UV powder coated MDF surface. These results only further demonstrate the durability and longevity of powder coated MDF components.

The use of antimicrobial UV cured powder coating on many commercial, industrial and household products along with normal cleaning practices may help stop the spread of harmful microbes. Antimicrobial powder coating offers protection for surfaces against harmful micro-organisms, stains and discoloration, which can lead to premature product replacement. The effectiveness of the antimicrobial properties and the durability of the finish will ensure the continued demand for these coatings for years to come, relieving concerns about safety and answering the ever-important question: “is it safe to touch?”

Author: Michael Knoblauch, President Keyland Polymer UV Powder, LLC

Tel: +1 216 741 7915

Email: mfk@keylandpolymer.com

Website: www.keylandpolymer.com