UV Powder Coating on Novel Substrates

Powder Coated Tough Magazine, April/May 2013

Author Michael Knoblauch, President of Keyland Polymer

Heat-sensitive substrates such as medium density fiberboard (MDF) and plastics must have a lower temperature to cure the finish. UV curable powder coating is one answer to coating these types of novel substrates.

UV curable coating technology is increasingly being seen as the future technology in the area of industrial coatings. The technology represents one of the rapidly growing segments in the coatings industry, and is arguably emerging as the answer to the rising environmental concerns and stringent regulations. Several application-related advantages come to serve the technology that include absence of pot life issues, lower energy costs, fast cure speed, and reduced environmental impact.

According to Global Industry Analysis Inc., one-component UV curable coating ranks among the fastest coating chemistries available in the present context. To cure one-component, UV curable coating takes few seconds to minutes, which makes it more ideal for use in applications that require faster turnaround time.

Thermoset or thermally cured powder comings were developed in the 1960s as functional coatings and have been adapted and developed for a variety of applications. As those of us in the industry know, powder coatings give superior wear resistance, barrier properties, and cost effectiveness. They have no volatile organic compounds (VOCs) or hazardous air particulates (HAPs).

The first commercial applications for UV curable powder coatings in the United States began in 1998. They were an automotive radiator and an industrial motor. In 2001, Decorative Veneer built the first UV curable powder coming facility for MDF in Plainwell. Mich., and that was followed by Radex in London, Ont.

Additionally, application facilities were built in Europe for MDF and PVC cushion floor. Then in 2005, the Decorative Veneer system moved to Cleveland and the company DVUV formed. Its key markets include retail, healthcare, education and office furniture, and specialty applications. In 2006, Keyland Polymer Ltd. formed to develop, formulate, and manufacture UV curable powder coatings for DVUV and other customers.

UV Powder Coating

UV cured powder coating technology is a rapidly growing segment of the coatings industry and is emerging as the answer to rising environmental concerns and stringent regulations on coating processes. The technology has lower energy costs, one of the fastest cure speeds, and offers a reduced environmental impact. These are just a few reasons why one should strongly consider using UV curable powder coating technology.

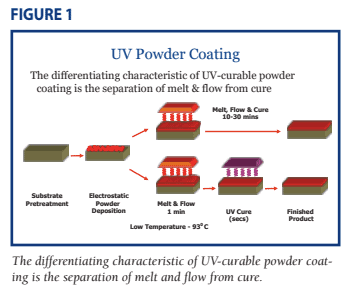

The electrostatic powder application function of a UV cured powder coating system and a thermoset powder coating system are exactly the same. However, the differentiating characteristic of UV curable powder coating is the separation of melt and flow from cure (Figure 1). This separation enables the processor to control the melt/flow and cure functions with precision and efficiency, and helps maximize energy efficiency, improve material utilization and increase production quality of UV curable powder coating systems. Since the introduction of UV curable powder coating, external market conditions have changed, making the advantages and benefits even more compelling.

This separation enables the processor to control the melt/flow and cure functions with precision and efficiency, and helps maximize energy efficiency, improve material utilization and increase production quality of UV curable powder coating systems. Since the introduction of UV curable powder coating, external market conditions have changed, making the advantages and benefits even more compelling.

Benefits of UV Powder

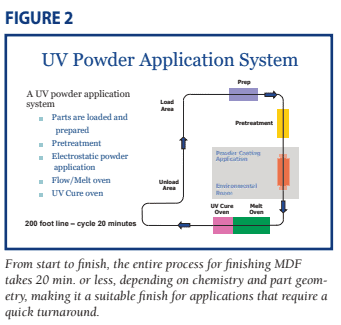

UV curable powder coating is one of the fastest coating chemistries available. From start to finish, the entire process for finishing MDF takes 20 min. or less, depending on chemistry and part geometry, making it a suitable finish for applications that require a quick turnaround. A completed part requires only one coat, allowing increased production with 40 to 60 percent less energy than other finishing processes (Figure 2).

The UV curing process reduces throughput times, generating a number of efficiency benefits such as less time waiting on daily startup and shutdown, increased finishing capacity, a reduced number of parts on the finishing line, and a reduction in defects and rework.

The UV powder itself is environmentally friendly, containing no solvents, VOCs, HAPs, monomers or additives, making it safe to use. A spill can be swept or vacuumed with no residual damage to equipment or property. The process also offers a small carbon footprint. It can be recycled or repurposed and doesn’t require operating permits.

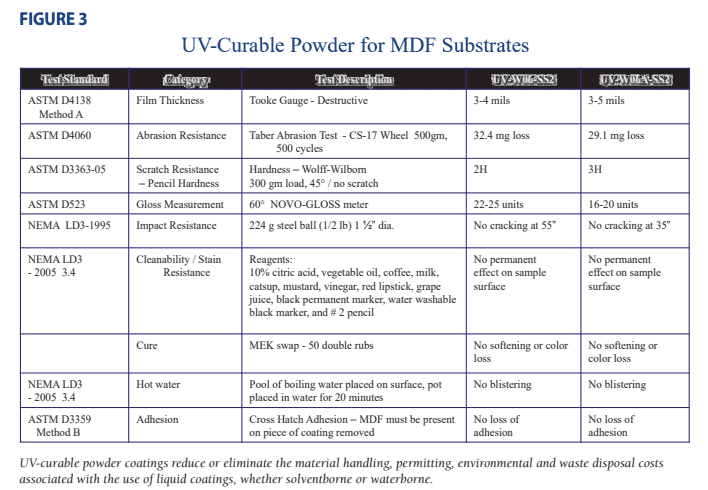

Another major benefit of powder coating is the ability to recapture sprayed powder and reintroduce it into the finishing operation. In fact, powder over-spray is reclaimable up to 98 percent. UV curable powder coatings reduce or eliminate the material handling, permitting, environmental and waste disposal costs associated with the use of liquid coatings, whether solventborne or waterborne. They also have better life cycle advantages than liquid coatings because solid materials are easier to blend, process, control and apply than liquid materials (Figure 3).

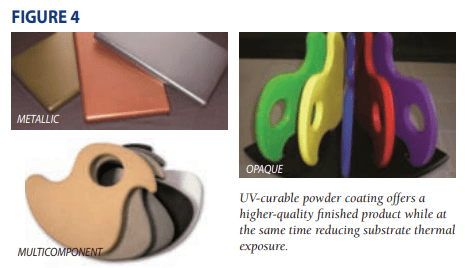

UV curable powder coating offers a higher-quality finished product while at the same time reducing substrate thermal exposure. This is especially important when finishing MDF or other novel substrates, as these materials are sensitive to extended periods of heat. The coatings can be formulated to specific products and are available in a range of color, gloss and texture (Figure 4).

Because the process is faster and provides a higher ROI, you can process more material in a shorter time period, and the total applied cost is lower compared to other finishing systems.

Because the process is faster and provides a higher ROI, you can process more material in a shorter time period, and the total applied cost is lower compared to other finishing systems.

Manufacturers and service providers are challenged by the demand for innovative products and services, and are further challenged to ensure sustainability throughout the supply chain. Customers make intentional and conscious buying decisions based on criteria and standards that define products and services as sustainable. Consumers are actively seeking materials and processes that are safe — safe to make, safe to use and safe to dispose.

Cost Benefits

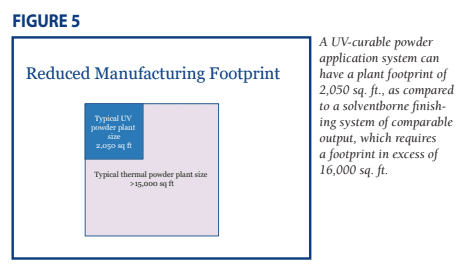

While UV-curable powder coatings have numerous advantages over solventborne and waterborne finishes from a chemistry standpoint, they also have advantages from a cost-savings standpoint. A UV curable powder application system can have a plant footprint of 2,050 sq. ft., as compared to a solventborne finishing system of comparable output, which requires a footprint in excess of 16,000 sq. ft. Assuming an average rental of $6.50 per sq. ft. per year, an estimated UV cure system; annual cost would be S 13,300 compared to $104,000 for solventborne (Figure 5).

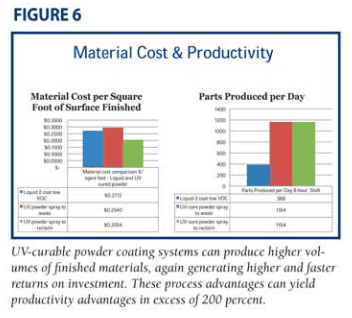

UV curable powder coating systems can produce higher volumes of finished materials, again generating higher and faster returns on investment. These process advantages can yield productivity advantages in excess of 200 percent, demonstrating that the adage “time is money” is still valid (Figure 6).

UV curable powder coating systems can produce higher volumes of finished materials, again generating higher and faster returns on investment. These process advantages can yield productivity advantages in excess of 200 percent, demonstrating that the adage “time is money” is still valid (Figure 6).

Conclusion

With increased awareness of sustainability, efficiency and safety, UV curable powder coatings offer numerous opportunities for future growth. The technology and process is fast, clean and green. The innovative chemistries used and the application technologies involved deliver more value at a lower cost, displacing existing finishing chemistries and application technologies. Their significant and compelling features are pan or the reason UV curable powder coatings and application technologies are gaining popularity.

Michael Knoblauch is President of Keyland Polymer ltd. He can be reached at mfk@keylandpolymer.com